|

|

|

| HART /

PROFIBUS DP Gateway GT200-HT-DP Application in cement industry

|

|

Keywords

|

| HART, PROFIBUS, HART/PROFIBUS

conversion module

|

|

System Composition

|

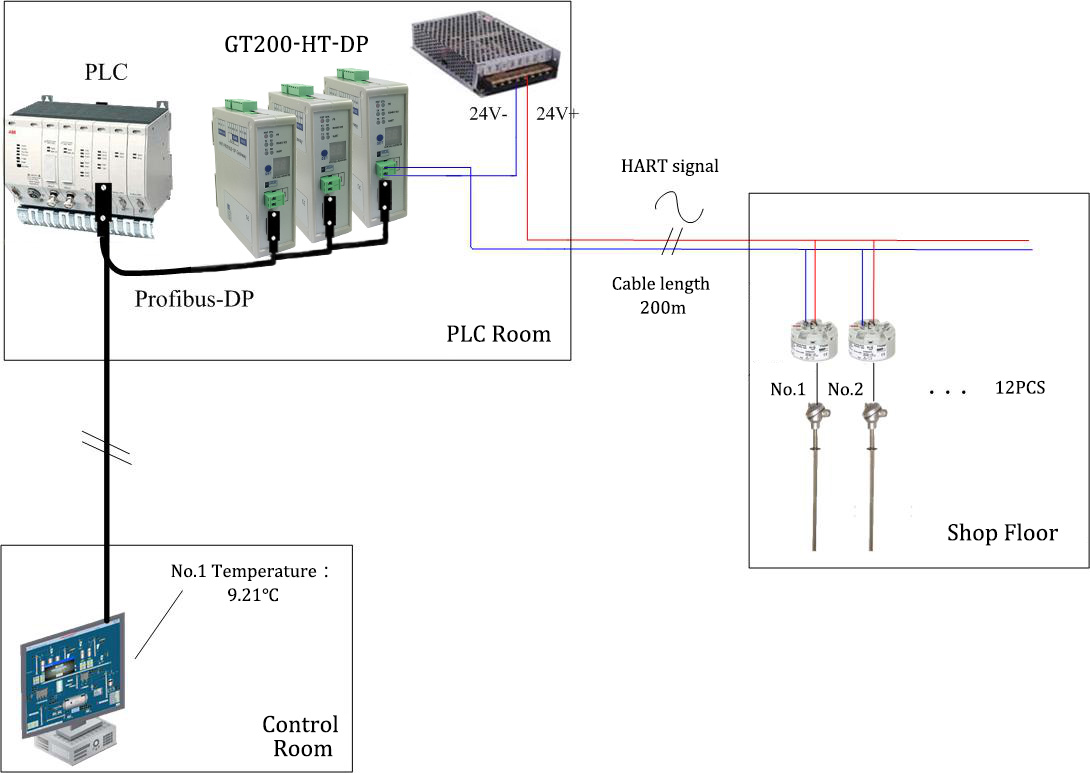

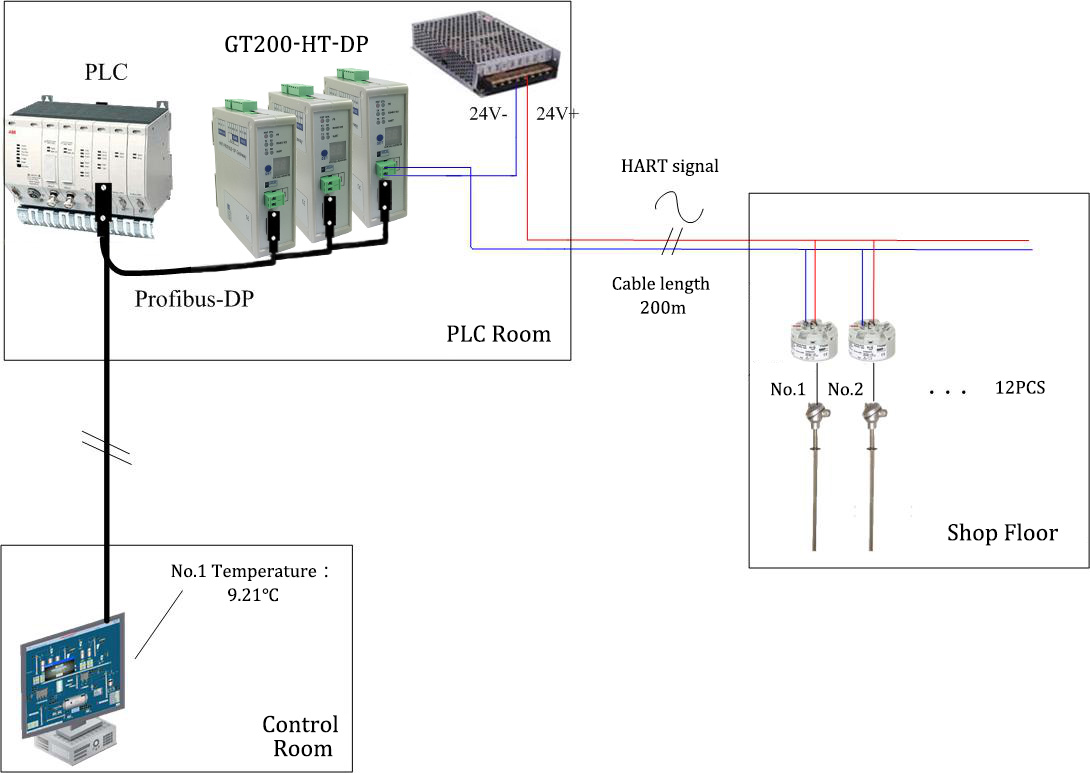

The entire production line's automatic

control system consists of three parts: field equipment, various controllers in the PLC room,

and central control system in the control room. The central control system communicates with

various PLC controllers via the PROFIBUS DP. The controller is responsible for collecting or

controlling all kinds of field devices 100 meters away.

There are 36 temperature

measurement points and 56 pressure measurement points at the rotary kiln site. The control

system needs to monitor these measurement points in real time. In order to save the cost of

the cable, the instrument on these measuring points is two-wire system (two power lines),

among them, 36 temperature transmitters adopt HART communication protocol. SST Automation

HART/ PROFIBUS DP gateway GT200-HT-DP converts the

HART protocol data of the on-site temperature transmitter to PROFIBUS data and uploads it to

the control system.

|

|

|

The chart is wiring diagram in the

shop floor. From the rotary kiln to the PLC control room, it needs three pairs of 24V power

cords up to 200 meters in length. For each pair of power cords, 12 temperature transmitters

are connected in parallel in the field, and three GT200-HT-DP and 24V power

supplies are connected to the PLC control room.

GT200-HT-DP can connect up

to 15 on-site HART protocol devices and map the temperature values of the 12 temperature

transmitters to the PROFIBUS, so that the control system in the control room can read data of

each temperature transmitter by addressing the GT200-HT-DP gateway, then

handle with corresponding questions.

|

|

HART/PROFIBUS DP Gateway Configuration

|

In this case, customer needs to

configure the GT200-HT-DP and HART

instuments:

a.Configure HART slave device short address

b.Configure GT200-HT-DP in SST-HT-CFG

software and command for read/write HART slave device parameter

c.Set PROFIBUS address

d.Import GT200-HT-DP GSD file and

proceed modeling in PROFIBUS DP master control system

|

Conclusion

|

The advantages of HART/ PROFIBUS gateway GT200-HT-DP:

1. Reduced wiring costs

2. Increased control capabilities, through the GT200-HT-DP gateway, the measured

value of the instrument is directly transmitted to the control system through the PROFIBUS. The

control system can directly read out the measured values in the field and facilitate the subsequent

processing.

|

|

|

|

California Office:

3200 E Guasti Rd, STE 100, Ontario, CA 91761

Tel: 844-606-2886 (US & Canada)

+1 (626) 899-6290

(International)

|

Asian Pacific Office:

6E, Bld 3, 518# Xinzhuan Rd, Songjiang District,

Shanghai 201612,

China

Tel: +86-18917828842

|

|

|